clean puzzle journey

For years I’ve wanted to make a puzzle, I just didn’t know how. It’s an idea I’ve had brewing in the back of my mind for ages. For me, it’s always brought back a nostalgic feeling. During power outages as a kid, me and my family would always play board games and put together puzzles to help pass the time, holding flashlights over our heads laughing together while making popcorn over the fireplace. It was such a blast. Sometimes you’d finish the puzzle, other times you’d put it back in the box for the next group activity like playing Monopoly or Sorry.

For some reason each time I've bought a puzzle, it comes in this flossy shrink-wrapped plastic protecting the box, and once opened more plastic bags holding the pieces together with some instructions that showcase the image, even though it’s on the cover of the box. It ends up wasting plastic for a cardboard box that holds puzzle pieces just fine.

LESS PLASTIC PLEASE

After deep-diving into getting an actual puzzle made, I realized a significant gap in the supply chain. Plastic. While that isn’t new, what is new is this standard for plastic wrap and bags to make products look more polished and pretty. Their reasons are for shipping and presentation. As it’s functional for those purposes, they aren’t needed.

For the puzzle, I had to interview factories to see if they were the right fit for Alimo. Making sure they understood my ethos and had the ability to work hands-on with their workers to use no plastic in the production.

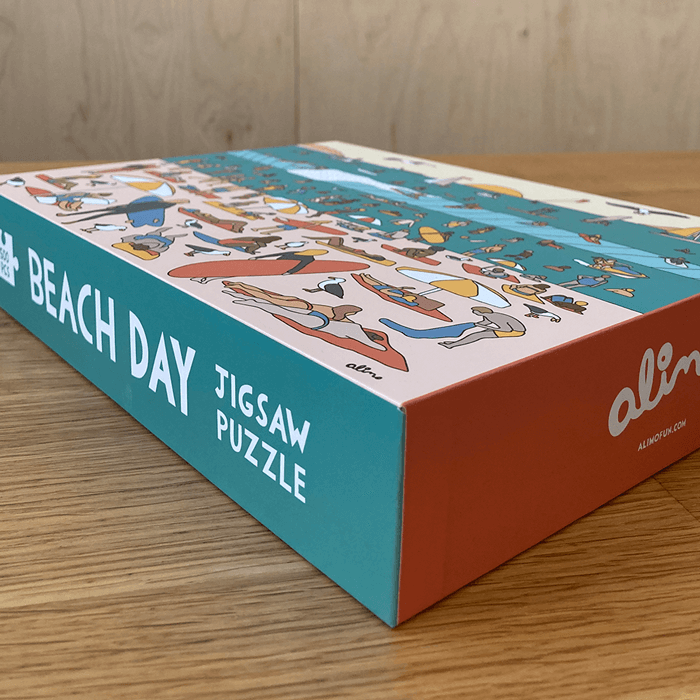

Our solution was simple: eliminate plastic wrap on the box, and remove poly bags that hold the puzzle pieces. To help solve the shipping problem, we added a slim cardboard sleeve as an extra layer so no pieces could fall out during shipment.

For us, this was a big victory.

RECYCLE

After finding the right factory, the next step was sourcing recycled materials to produce the puzzle and packaging. This added an additional layer that made things a bit more complicated. The easy button is using raw material. While raw materials can produce better quality for some goods under the right circumstances, a puzzle didn’t apply to this use case. Recycled material produced the same, if not better puzzle pieces in the end.

Our solution sourced the packaging with FCS-recycled material that comes from reclaimed or re-used material. The puzzle pieces are also 100% recycled.

THE WHOLE PACKAGE

By eliminating all plastic used in this puzzle, we intentionally removed any instruction packet inside the box as the cover is the illustration. Once you’re finished with the puzzle, quickly put the pieces back in the box for storage. Better yet, lay it right side up in the corner to use as art on the wall. This adds as a multi functional box for storage that is also art.